Home / Technologies /

Seeding – Planting – Technology

Our planting technology helps you increase your yield potential and reduce your production costs. With our solutions, you can plant the largest area in the optimal window, control seed delivery in the furrow, view the machine’s performance in real time, automate certain functions, such as driving, speed and tractor and planter/seeder functions, control input management and much more.

Automation and guidance

When planting, you need to make sure your tractor goes over the right area to promote healthy competition between your plants and optimize the planting area as much as possible. Also, since the planting window is very short, you need to accomplish the operation as quickly as possible. Our automation solutions allow you to plant your fields with a one-inch accuracy and optimize the working time to plant the maximum area in the shortest possible time. Whether it’s driving the tractor using GPS, turning and automating functions at headlands, our solutions are tailored to your company and its needs.

Input control

Our input control solutions ensure that you apply the target dose evenly regardless of your speed. In addition, combined with section control, they help you reduce overlap and skips.

Control your costs, eliminate under- or over-application and reduce your environmental impact with our solutions.

Planter Technology

Ready to get a near-perfect planting? John Deere technology is here to help.

MaxEmerge™ 5E

No more chains, drive arms, sprockets, hydraulic motors and other wear parts, which are all replaced by high-reliability electric motors. Get an accurate population and even spacing by decreasing vibrations that cause doubles and skips and increase your planting accuracy.

Plus, get accurate planting on a curve with curve compensation technology.

The ExactEmerge™ planter’s state-of-the-art, exclusive technology ensures performance, reliability and precision in your planting. It helps you increase your planting speed (up to 16.1 km/h) while ensuring unwavering accuracy and consistency in seed spacing so that you can make the most of your planting window.

SeedStar™ 3 HP Monitoring

With access to critical information about your planting and your planter, SeedStar™ 3 HP helps you make the necessary adjustments and decisions to improve your planting.

View the following information:

- Singulation (seed release performance)

- Unit downforce

- Ground contact

- Vibration

In addition, you have access to the following features:

- Row-by-row performance monitoring

- On-screen display and control of the down force system

- Different coloured icons for better visibility and a simplified experience

- Mapping of the target population and the planted population

- Controller that can be reprogrammed remotely by our staff (using JDLink™)

- Pressure alarm for liquid fertilizer

- Automatic quick start to make sure the feeder is full when restarting after a shutdown

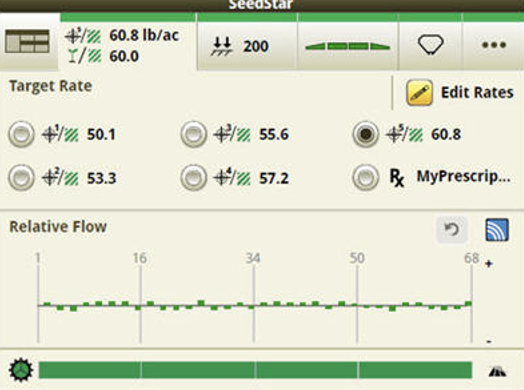

SeedStar™ 4HP Advanced Seed Monitoring

Compatible with ExactEmerge™ and MaxEmerge™ 5E planters, SeedStar™ 4HP lets you easily view your planter’s performance. Whether it’s to display multiple bar graphs/performance data at once or use the zoom feature, you’ll stay in control of your planter and planting.

In addition to the information provided by SeedStar™ 3, you will be able to:

- View multiple performance charts at the same time

- Navigate between the three default work set-up pages or create a custom one based on your preferences

- Use the zoom feature

- Make adjustments to the planter

- Easy adjust configurations from the work set-up page

- Use up to six different planting rates at the same time

Pneumatic furrow closing system

To achieve the best possible emergence:

- All seeds should be planted at the same depth and in soil where humidity and temperature are consistent

- The emergence of the first seed to the last must occur within a maximum of 24 hours.

- The seed must be in contact with the soil.

The seed must be in contact with the soil so that it absorbs the heat and moisture necessary for its germination. A tightly closed furrow ensures optimal seed-soil contact. Adjust the pressure on your closing wheels without leaving your cab.

With more than 25 positions, you will be able to precisely adjust the pressure applied by the furrow closing system based on field conditions.

Individual row downforce control

Emergence is the factor that has the greatest impact on your return potential. John Deere’s Individual Row Hydraulic Downforce system (IRHD) ensures optimal soil contact for each of your planter’s units. This automatically adjusts according to changing field conditions (type of soil, compaction, residue).

Le système de pression au sol individuel hydraulique de John Deere (IRHD) permet d’assurer un contact au sol optimal pour chacune des unités de votre planteur. Celui-ci s’ajuste automatiquement en fonction des conditions changeantes du champ (types de sol, compaction, résidus).

Row cleaner adjustment system

Residue is a limiting factor in achieving your optimal yield potential.

It can:

- prevent the soil from warming up quickly

- have an impact on the performance of the emergence (depth of seeding and germination), pre-emergent herbicides, and the furrow closing system.

The row cleaner adjustment system allows you to adjust the tool’s aggressiveness according to the field conditions.

Vacuum automation

The vacuum level has a direct effect on the planter’s singulation performance. If the suction is too low, some seeds will be missing in the furrow and, conversely, if the suction is too high, you will have doubles. With automated vacuum control, suction remains constant throughout changing field conditions. Program the desired vacuum level and the system will control the hydraulic flow of the oil outlet to maintain constant suction.

Automated Folding

This technology automates the planter’s folding to switch it from transport mode to planting mode and vice versa. This will help you save time spent configuring equipment when you arrive on the field.

ExactRate™

ExactRate™ helps you reduce your input costs, minimize your exposure to chemicals, and quickly detect variations in applications to prevent input over- or under-application.

- 1% to 12% (4.3% on average) reduction in product application thanks to row-by-row control

- Rates up to 20% more accurate in curves compared to the system without curve compensation

- Change rates quickly and/or execute prescriptions without changing orifices

- Adapts to speed changes by making sure to keep the target rate

- In-cab flow detection and monitoring system

PUK Planteur

Already own a planter and are satisfied with it but want to take advantage of the latest technology? Ask us! Most of this technology can be added to certain John Deere planters.

Seeding Technology

ActiveCAL™

The more frequently you calibrate your equipment, the more accurate it will be! With ActiveCal™ technology, you can calibrate your planter directly from the cab without having to go back and forth to the cart. A number of variables, such as the specific weight of the product or changing weather conditions throughout the day will have an impact on any volumetric metering system. With the ActiveCal™ system, calibration can be done directly from the operator’s cab while planting to minimize variations in product metering.

SectionCommand™

For the first time, meter sections are now controlled by electric motors.

Each of the sections is controlled by its own electric motor. This eliminates the need for a variable-rate hydraulic motor and enables variable/prescription planting as well as minimizes overlap thanks to the section control feature.

TruSet™ for seeder

Accurate and consistent seeding depth is key to increasing yield potential. With the TruSet™ system, the operator can adjust the seeder’s downforce directly from the cab according to changing field conditions.

PUK Semoirs

Already own a seeder and are satisfied with it but want to take advantage of the latest technology? Ask us! Most of this technology can be added to certain John Deere seeders.

Telematic

Telematics includes the following technologies:

- Equipment usage information

- Equipment health monitoring

- Equipment optimization

- Automatic data backup to the cloud

- Remote connection and information sharing between machines.

The optimal planting window is very short. With our telematics solutions, you can control the quality of the planting work carried out. In addition, the tractor and the planter will alert you of problems so that you can intervene proactively to avoid downtime in the field and plan maintenance work.

Your planting data is vital in helping you control planting quality, choose your favourite varieties, identify areas of compaction and much more. With our telematics systems, you are connected to your equipment and have quick and easy access to this information.

In addition, when you choose to share this information with our support teams, we can help you optimize your tractor and planter. We will also track equipment alerts so that action can be taken proactively to minimize downtime and plan maintenance work during less critical periods.

Decision-making support

Planting is the most critical operation of the year. Once the seed is in the ground, your maximum yield potential is determined. After this, your decisions and factors out of your control will affect it. You therefore have to make sure that the seed is perfectly placed in a furrow where the humidity is uniform, that it is placed at a consistent depth, that it is equally spaced, that there are no air pockets or residue, and that the furrow is properly closed. In addition, the fertilizer must also be properly placed to be available to the plant at critical stages, and everything must be done in the optimal short window.

Our tools help you plan your planting based on upcoming opportunity windows and create prescription maps based on past yields, soil maps, seeding maps and more. With these tools, you will be able to see how the work is progressing and save it as you go, as well as better plan your operations and make better decisions based on accurate, available and actual data.

Operations and equipment optimization

To get the full return on your investment, you need to optimize your equipment’s performance (tractor and planter/seeder). This means making sure your equipment is properly maintained and adjusted to field conditions.

Our tools help you analyze performance, schedule your maintenance, adjust equipment according to conditions and monitor performance and progress.

JLD-Laguë Service Xpert

![]()

The JLD-Laguë Xpert Service is our team of 6 specialists dedicated specifically to precision agriculture, tasked with supporting you and ensuring that your precision agriculture tools are used to their full potential.

Learn more about precision agriculture and our Xpert Service today by contacting our call centre 24/7 at 1-877-4470-2583.

Xpert Service Programs