Home / Technologies /

Harvesting

Our harvesting technologies help you in many areas. To reduce your ecological footprint, quickly and simply optimize the combine’s operation and efficiency, reduce harvest losses, manage production costs, limit the risk of accidents, reduce the operator’s workload, obtain accurate documentation and much more.

Automation and guidance

Now is the time to reap the fruits of your labour!

To help you harvest efficiently, our automation and guidance solutions take care of steering your combine, ensuring that you harvest across the full width of your header. In addition, coverage sharing ensures that your yield map data will be accurate.

Telematics

Telematics includes the following technology:

- Equipment usage information

- Equipment health monitoring

- Equipment optimization

- Automatic data backup to the cloud

- Remote connection and information sharing between machines.

Harvest operations are critical. With our telematics solutions, you can control the quality of harvesting work. In addition, your combine or tractor will alert you in case of problems so that you can intervene proactively to avoid downtime in the field and plan maintenance work.

Your harvesting data is essential to help you control the quality of the work done, compare the effectiveness of different products/varieties, target opportunities for improvement and much more. With our telematics systems, you are connected to your equipment and have quick and easy access to this information.

In addition, when you choose to share this information with our support teams, we can help you optimize your tractor or combine. We will also track equipment alerts so that action can be taken proactively to minimize downtime and plan maintenance during less critical periods.

Harvesting technology

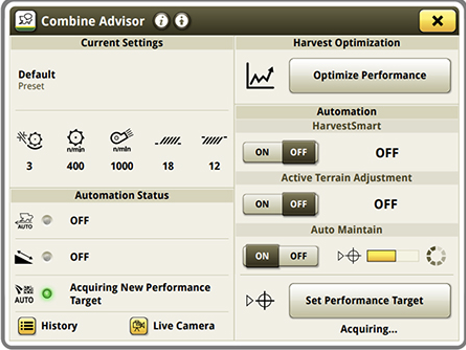

Combine Advisor™

Combine Advisor™ is the combination of various technology designed to maximize your profits during harvesting. This technology helps operators configure and optimize the combine. It then automates the combine to maintain performance targets as conditions change.

Active Terrain Adjustment

The Active Terrain Adjustment feature is a system that enhances grain quality and minimizes grain loss when going up or down a slope.

This feature allows you to:

- Achieve the same loss level as when harvesting on level ground (on slopes of up to 10°)

- Reduce residues by up to 35% on of 12- to 16° inclines

- Set automatic adjustments on slopes

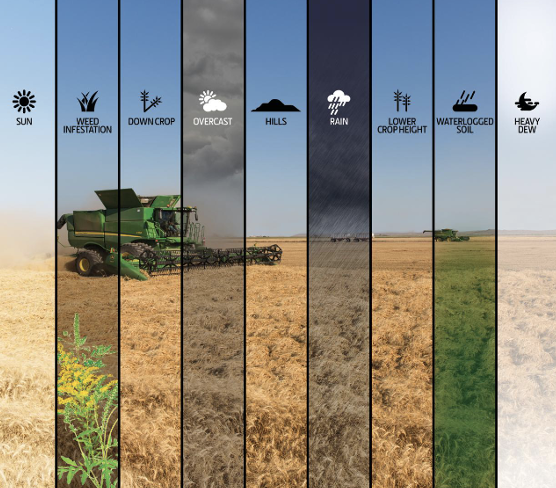

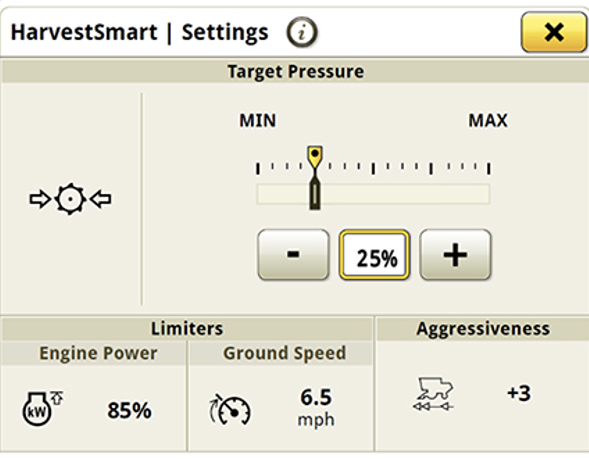

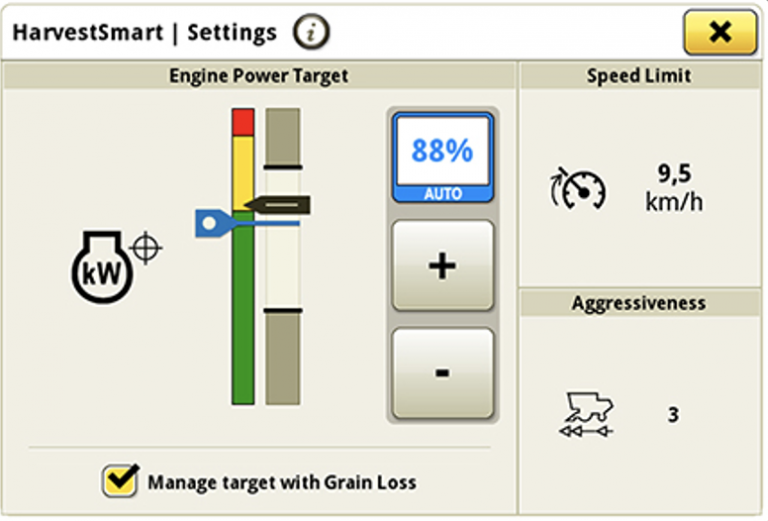

Harvest Smart™

Harvest Smart™ is an adaptive technology that allows you to control and automate the combine’s ground speed during harvesting. This allows for better combine power utilization by automatically changing the ground speed to compensate for variations in crops that are not readily visible to the operator.

By using Harvest Smart™, you will enjoy the following benefits:

- Increased machine performance

- Reduced operator fatigue and stress

Auto Maintain

Auto Maintain and ActiveVision™ cameras automatically adjust five of the combine’s main features. When equipped with this technology, the combine will maintain the performance of everything from grain loss and grain quality to the cleanliness of the grain in the grain tank.

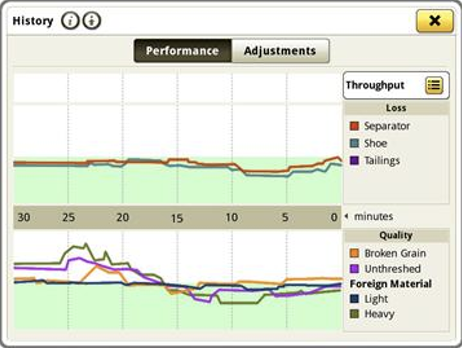

ActiveVision™ Camera

ActiveVision™ cameras can detect cracked and unsegregated grain. They can detect both light and heavy foreign material and make the necessary modifications to improve the quality of the grain.

VisionTrack

The VisionTrack system enables operators to monitor losses that may be occurring over the separator and cleaning shoe from inside the cab.

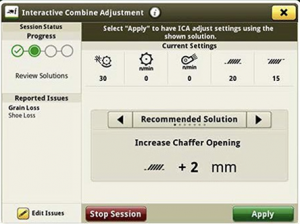

Interactive Combine Adjustment

The interactive combine adjustment system simplifies the operator’s task when adjusting the combine by recommending certain changes based on observations of the combine’s performance.

Engine Speed management

This technology reduces the engine RPMs during road transport while still maintaining a productive ground speed.

- Up to a 20% savings in fluids

- Decreased noise

Harvest setup application

This application built into your combine screen allows you to view and configure the combine’s various features:

- Increase your productivity by decreasing the time spent setting up the machine

- Efficient combine operation since the configurations are all on one page

- Easy access to critical combine features

- Easy and direct access to combine optimization information and the ability to make changes to the settings

Machine Sync

This feature automates on-the-go unloading of the combine into the grain cart. The combine then takes control of the direction, position and speed of the tractor and grain cart, reducing the risk of an accident, increasing your productivity and allowing you to perform the operation at higher speeds. In addition, because grain cart operators see the grain tank fill levels in real time, they can decide which combine to unload first when harvesting with several combines.

ActiveYield™

Designed for farmers who want to increase the accuracy of their yield maps, the ActiveYield™ system recalibrates the yield sensor in real time in the field.

TouchSet™

TouchSet™ technology allows you to control the hydraulic features specifically related to the header (reel speed and direction, reverse, feeder house lateral tilt speed and sensitivity, feeder house raise and lower speeds).

Auto Swap

Optimize crop residue spreading.

Auto Swap technology automates the residue direction swap configured by the operator to compensate for wind direction on 180-degree turns.

ProDrive™

This technology allows you to maintain your harvesting speed in changing terrain conditions by switching from one speed range to another automatically. ProDrive™ also enables you to:

- Precisely control the combine speed

- Maintain a high level of productivity

- Maintain speed when four-wheel drive is engaged

- Maintain a maximum speed for each of the ranges selected by the operator (for more precise control during delicate operations)

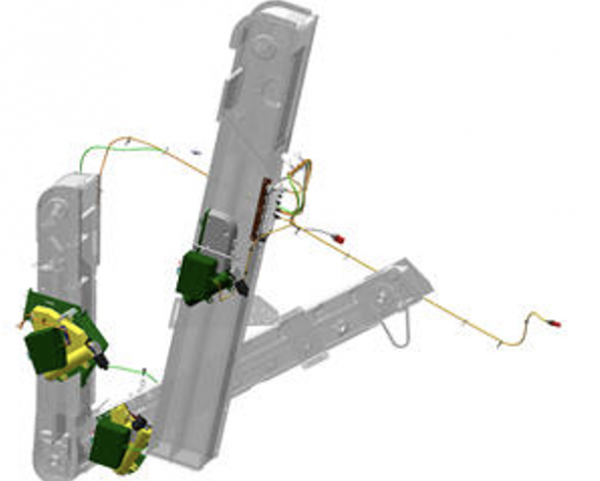

Autotrac™ RowSense™

- Installed on the header of the combine or forage harvester

- A set of sensors (RowSense™) determines the position of the plants to ensure that they are well aligned when harvesting them

Decision-making support

Now is the time to harvest!

Our tools enable you to compare varieties, verify the results of certain trials, plan your work, monitor progress, and make sure the work is properly executed.

Operations and equipment optimization

To get the full return on your investment, you need to optimize your combine’s performance. This means making sure your equipment is properly maintained and adjusted to field conditions.

Our tools help you analyze performance, schedule your maintenance, adjust equipment according to conditions and monitor performance and progress.

Specialty crop harvest documentation solution

This technology allows you to document harvest information for certain crops that are harvested by conveyor-driven equipment, such as potatoes, carrots, onions, beets and more.

JLD-Laguë Xpert Service

![]()

The JLD-Laguë Xpert Service is our team of 6 specialists dedicated specifically to precision agriculture, tasked with supporting you and ensuring that your precision agriculture tools are used to their full potential.

Learn more about precision agriculture and our Xpert Service today by contacting our call centre 24/7 at 1-877-4470-2583.

Xpert Service Programs